Types of Sanding

Anthony C • February 2, 2023

Aluminum Sanding Unveiled: Discover the Pros, Cons, and Differences of Each Type!

Orbital Sanding:

Pros:

- Versatile: Orbital sanders are suitable for various materials such as aluminum, stainless steel, wood, and other materials. If you’re a jack of all trades an Orbital Sander may be a great addition to your toolbox.

- Random pattern: Orbital sanders move in a random orbital pattern, reducing the risk of swirl marks and providing a smoother finish.

- Less aggressive: Orbital sanders are less aggressive than rotary sanders, making them easier on the arms, less dusty, and making them more suitable for sanding around delicate areas.

- Reduced risk of overheating: The random orbital motion generates less friction, reducing the risk of overheating the surface and the machine.

Cons:

- Less aggressive: An orbital sander will take longer to remove material, or in other words, remove a scratch. This is most-apparent when trying to tackle a large/deeps scratch or gouge.

Rotary Sanding:

Pros:

- High rate of material removal: Rotary sanders are very effective at removing material quickly, in other words, removing a scratch quickly.

- Aggressive: Rotary sanding is much more aggressive than orbital, allowing them to tackle tough surfaces and remove deeper scratches.

- Wide range of attachments: Various attachments can fit on and work well with your rotary. This includes sanding discs, cutting disks, buffs and wheels, polishing pads, brushes, and more.

Cons:

- Risk of swirl marks and gouges: Rotary sanders move in a circular motion, increasing the risk tough-to-cut of swirl marks on the surface. Because of their high speed, and less-forgiving circular motion, you can gouge the surface creating more work for yourself in the long-run.

- Less control: Rotary sanders can be more challenging to control compared to orbital sanders. This is most-apparent when running high speeds such as 9000rpm and 12000rpm.

- Potential for overheating: The continuous rotary motion generates more heat, and larger power consumption increases the risk of overheating the surface, the machine, and your hands if not used with caution. For the pros: It’s always a good idea to have multiple machines on-hand, if one gets too hot or breaks.

Differences:

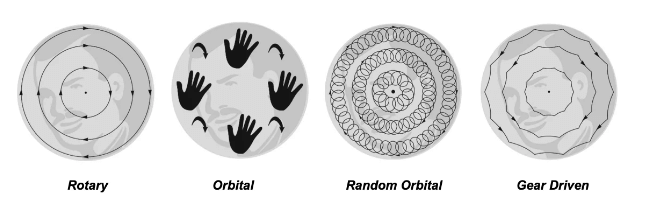

- Motion: Orbital sanders move in a random orbital pattern, while rotary sanders move in a circular motion.

- Aggressiveness: Rotary sanders are typically more aggressive and faster at removing material compared to orbital sanders.

- Finish: Orbital sanders provide a smoother finish with fewer swirl marks, while rotary sanders may leave more visible swirl marks if not used correctly.

Summary

Orbital sanding is suitable for lighter sanding tasks and provides a smoother finish with less risk of swirl marks, while rotary sanding is more aggressive and effective for heavy-duty sanding tasks but requires more caution to avoid swirl marks and overheating. The choice between the two depends on the specific requirements of the job.